In deep-sea or offshore mining for oil and gas, the durability and freedom from maintenance of all deployed machines over timespans of 10 to 30 years is essential. Achieving this is next to impossible with conventional materials – specifically, for example, with regard to wear components in pumps, pipe segments or nozzles. For this field of application, Fraunhofer IKTS, in collaboration with its Fraunhofer AdvanCer Alliance partners, is developing superhard, wear- and corrosion-resistant diamond ceramics.

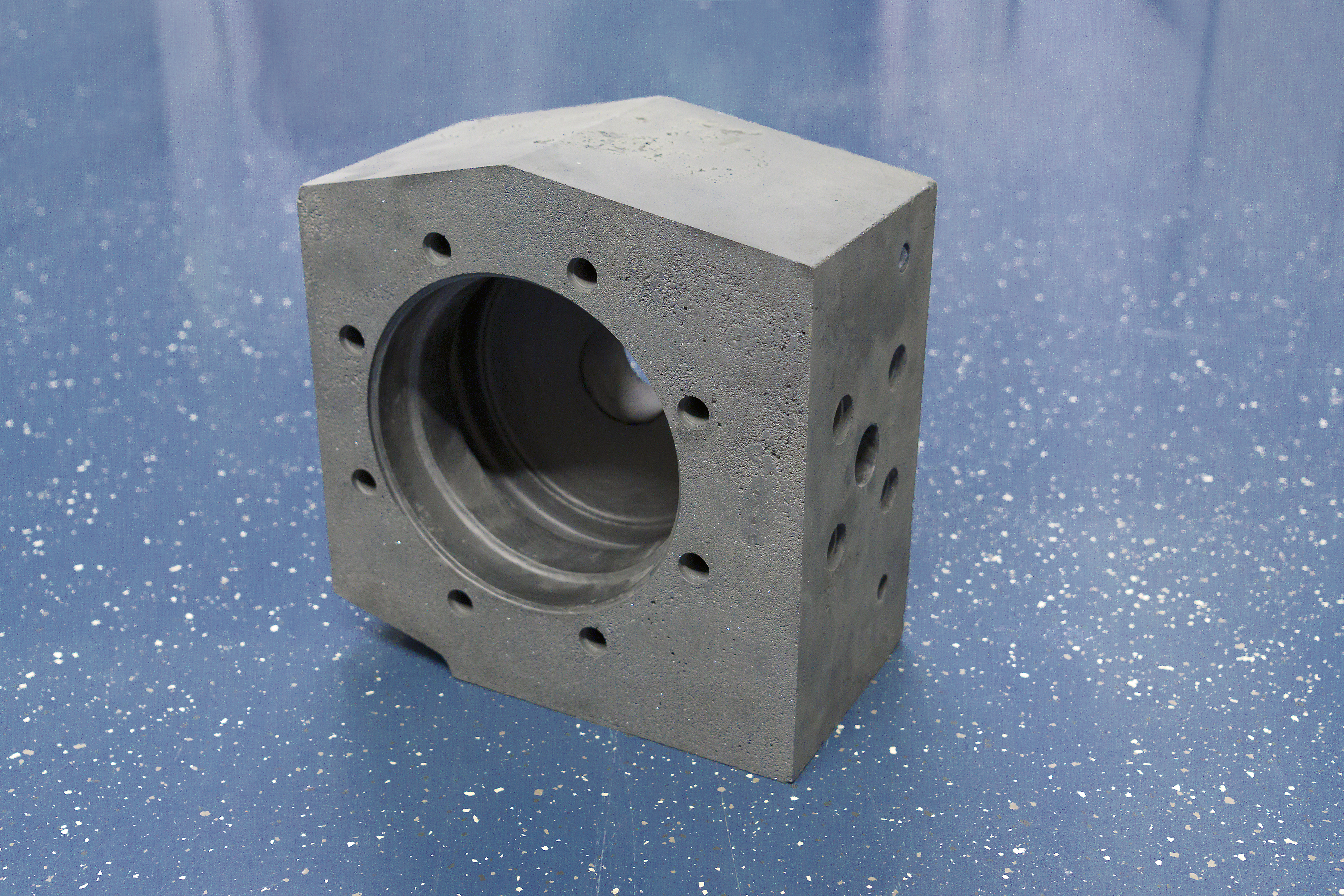

In contrast to commercial diamond materials, these novel diamond ceramics can be manufactured in a cost-efficient manner and in complex geometries using conventional ceramic technologies – on the one hand as compact components and on the other hand as layers of 300 to 500 μm thickness in highly stressed component areas. Thereby, the diamond preform is infiltrated with liquid silicon. During the infiltration, a three-dimensional framework is formed in which the diamond is chemically integrated. This SiC bonding results in higher strength of 450 to 500 MPa and a high corrosion resistance. In addition, tribological tests show that the wear resistance of the developed diamond ceramics is 10 times higher than that of commercial boron carbide materials and they have a wear behavior similar to that of superhard polycrystalline diamond (PCD).

The microstructures of the materials can be adjusted across a wide range allowing for the production of components with customized properties. The developed diamond ceramics open up new possibilities for manufacturing wear- and corrosion-resistant components cost-effectively for applications beyond the deep-sea area as well.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials