BladeMaker – Industrialized Rotor

The BladeMaker center has been set up as an open platform to the industry for the joint development and testing of innovations together with Fraunhofer IWES and 15 partners. The goal is to achieve savings of up to 10% through more efficient production processes, the use of innovative

materials and carefully selected automation approaches. A verified cost model that has been developed in close collaboration with a large number of blade manufacturers has confirmed the feasibility of this aim.

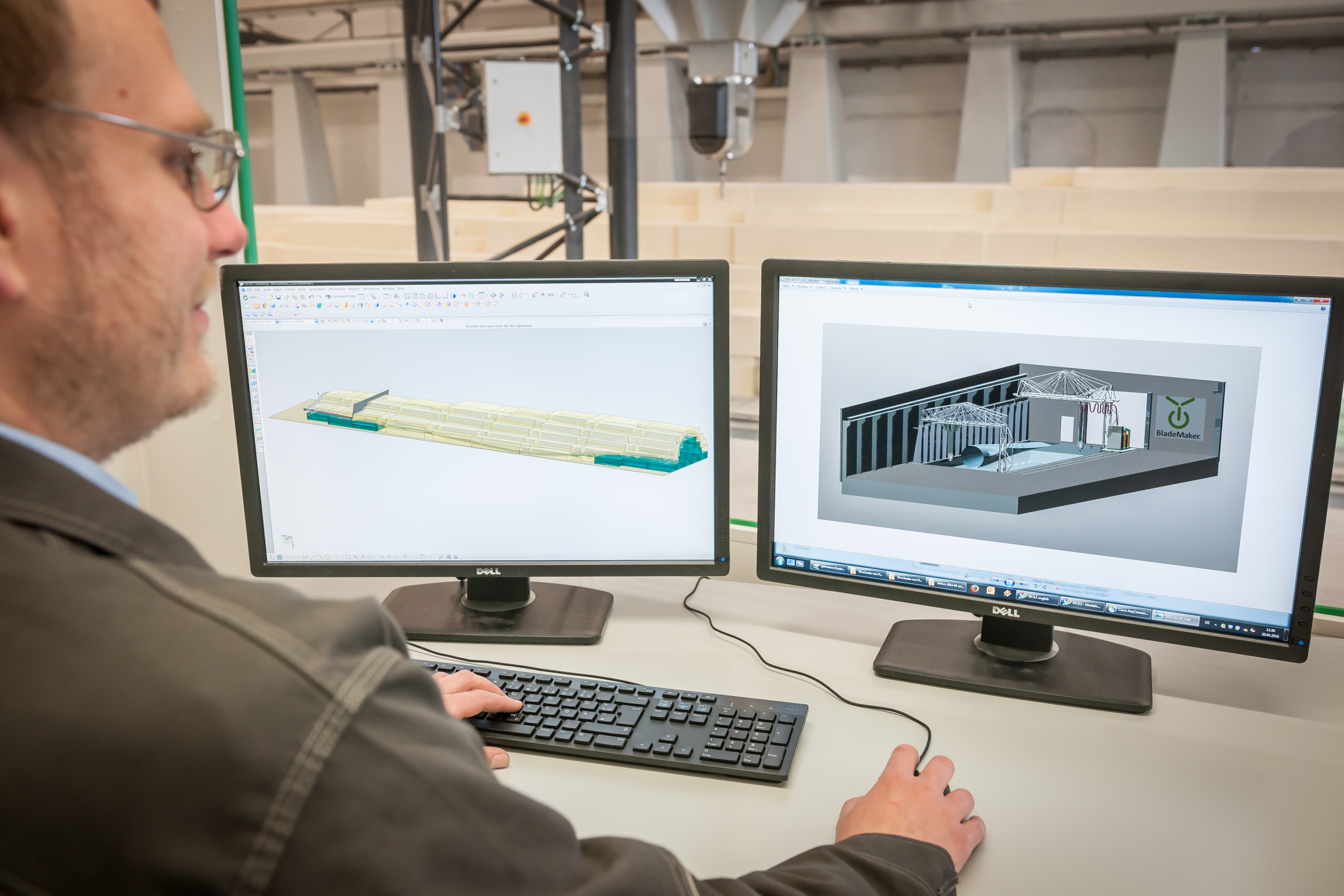

Blade sections measuring up to 25 meters (scale 1:1) for blades in the 50-meter class can be used in the workshop. The L-shaped design of both gantry systems offers two advantages: First, loading and unloading from the side is possible. Secondly, the robot combines the precision of a milling machine with a load-bearing capacity of up to 500 kg. Contrary to the general trend in composite manufacturing, linear drives with additional rotational degrees of freedom are preferred to a robot solution. This concept offers advantages with regard to precision and flexibility in setting up new processes. The next milestone will be the production of a model blade which will pass through the various production steps. This will provide an opportunity to identify areas for improvement as well as compare and assess results.

Integrated machinery concept

The opening of the “BladeMaker Demonstration Center” marks a major milestone for the publicly funded “BladeMaker” research project. In addition to investing in infrastructure, innovations along the complete process chain of blade manufacturing are also to be developed. The requirements of an integral solution for the industrialization of the entire rotor blade manufacturing process are in part contradictory. The

key processes involved in the manufacturing of the rotor blade structure made of fiber composites require high loading of the machine for the semi-finished products to be processed, after all a rotor blade in the 50 m class can weigh up to 12 tonnes. Yet, on the other hand, the prerequisites in terms of accuracy are not as demanding as for subsequent machining; here tolerances of just a few fractions of a millimeter are necessary at times. The integrated machine concept with its high speed and low tolerances is able to satisfy the demands of both production and further processing.

Vertical integration of design and production

The two gantry robots made of fiber composite serve to frame the working area for blade sections.

They move along the lines at a maximum speed of 2.5 m/ second. A heavy-load platform for transporting the semifinished products and materials is towed along the floor to facilitate the setting up of the gantry. The CNC control from one of the project partners allows the design and production stage to be linked.

The machine is programmed and operated via a CNC control, which, in this form, represents a new approach. The advantages of simple handling and vertical integration of design and production in order to simulate the process steps in advance can now be exploited for the very first time. Given the structural design of the former building, integration of the portal system presented no problems at all.

One gantry robot fits various production steps

In contrast to a purely automated approach, “BladeMaker” is focused on the industrialization of the entire process. In this context, new materials or the application of the semi-finished products have to be improved to open up further opportunities for reducing costs and manufacturing time. In addition to the direct tooling approach, Fraunhofer IWES has set up an innovative process chain together with specialized partners for

the manufacturing of rotor blade molds. Thanks to the special gantry robots made of fiber composite structures, various production steps, which would normally be conducted at different machines, can be performed at the same workstation by simply changing the process head.

Based on the results of the generic cost model for rotor blade production, the main cost drivers have been identified. The production of the spar cap, positioning of the textile blanks for the root area in the mold through to alignment of the layers, innovative in-situ core concepts, direct infusion of the resin, application of the adhesive, and surface finishing to prepare for varnishing, all offer potential for cost savings.

The manufacturing of rotor blades still demands a high degree of manual labor. This is due to the low number of pieces in each production lot compared to the automotive industry for example: Whilst in the latter sector, models roll off the line hundreds of thousands of times, the tool mold for a rotor blade is only used as a template a few hundred times. Comparing the weights of components from blade and automotive production, the former are much heavier. Yet, for manufacturers, the ability to produce parts more quickly and with a constantly higher level of precision can result in significant cost advantages.

Full-scale demonstration in 2017

The project will end in fall 2017 with a full-scale process demonstration using a blade design developed by Fraunhofer IWES that will be available to interested parties. The results of the “BladeMaker” project will give quality-conscious manufacturers a competitive edge and, ultimately, also render the generation of wind energy more cost-efficient. The equipment in the “BladeMaker Demonstration Center” is available to the

blade industry as well as material suppliers and mechanical engineering companies. The project is funded by the German Federal Ministry for Economic Affairs and Energy to the tune of around € 8 million.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials