The medicine of the future is biological. And the future has already begun: Biomolecules are already used as active ingredients and first cell-based implants are fully integrated into the organism.

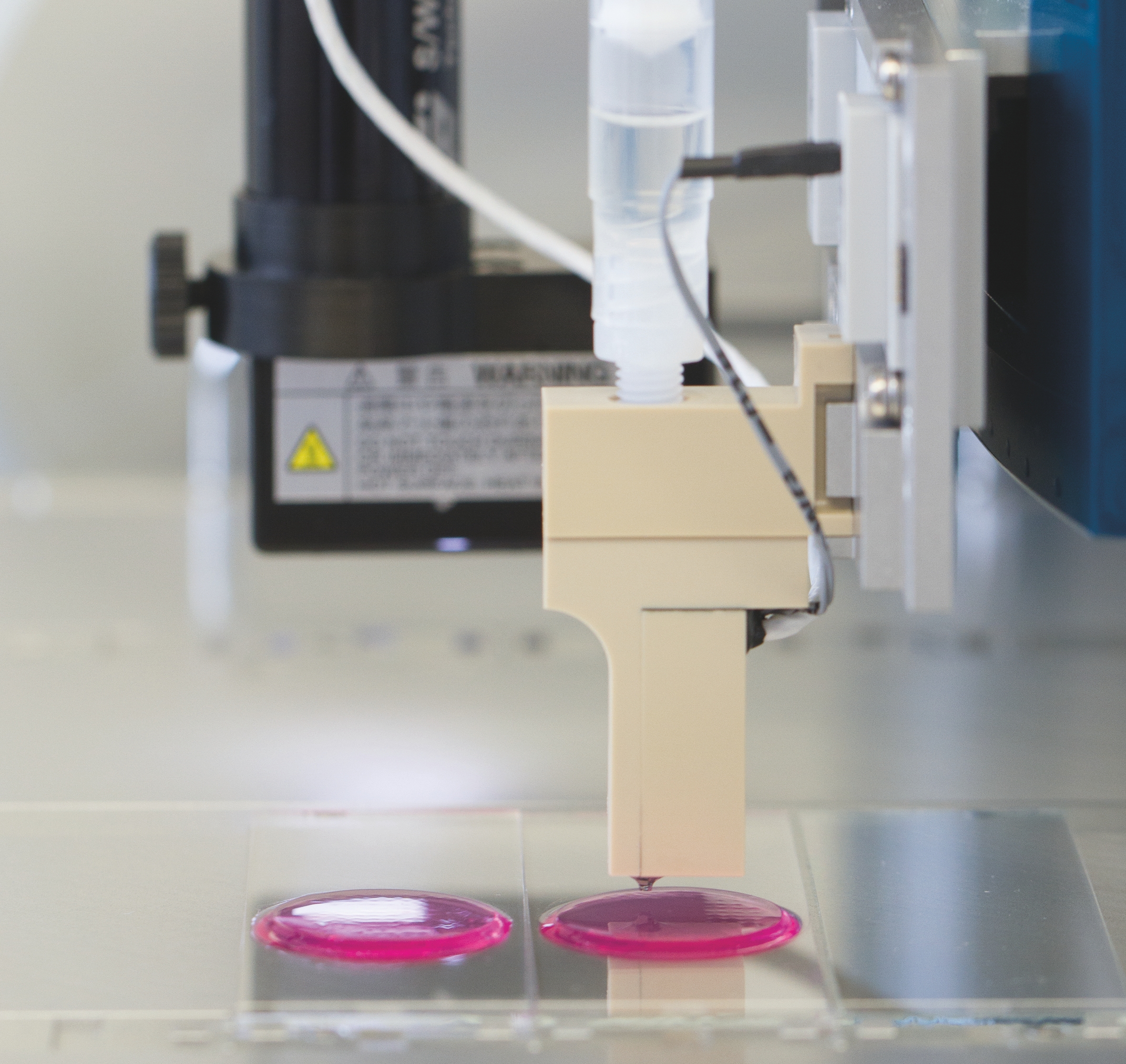

In order to turn the concept of biological replacement tissue into tangible reality, scientists at Fraunhofer IGB are optimizing biological materials for processing with 3D printing techniques. They use the molecules that are derived from the natural matrix of biological tissues such as hyaluronic acid or gelatin. By chemical modification of the biological molecules the viscosity and the gelling behavior can be controlled and crosslinkable groups can be introduced. Biopolymer solutions are provided that are particularly suitable for liquid handling and are used in printing and dispensing processes, such as low viscous gelatin solutions that can be processed at temperatures up to 10°C without gelling.

By means of a photo stimulus, stable hydrogels can be produced from these biomolecule solutions by cross-linking. Depending on the crosslinking density, the mechanical and biological properties of these hydrogels can be adapted to those of native tissue. This modular system of modified biopolymers is increasingly being tested for the construction of three-dimensional model tissue, so-called bioprinting, and for pharmaceutical formulations.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials