Although flexible and cost-effective printed touch displays are still a vision of the future, they are predicted to have a wide range of application. Their advantage is freedom of design their easy adaption since it is possible to roll out, so to speak, the display film. In addition, the cost-effective manufacturing process has low material costs compared to other methods while maintaining the good sensor characteristics. The material can also be produced on a large scale. Last, but not least, the polymer-based touch displays are lighter and more robust than the conventional hard glass-based displays available today.

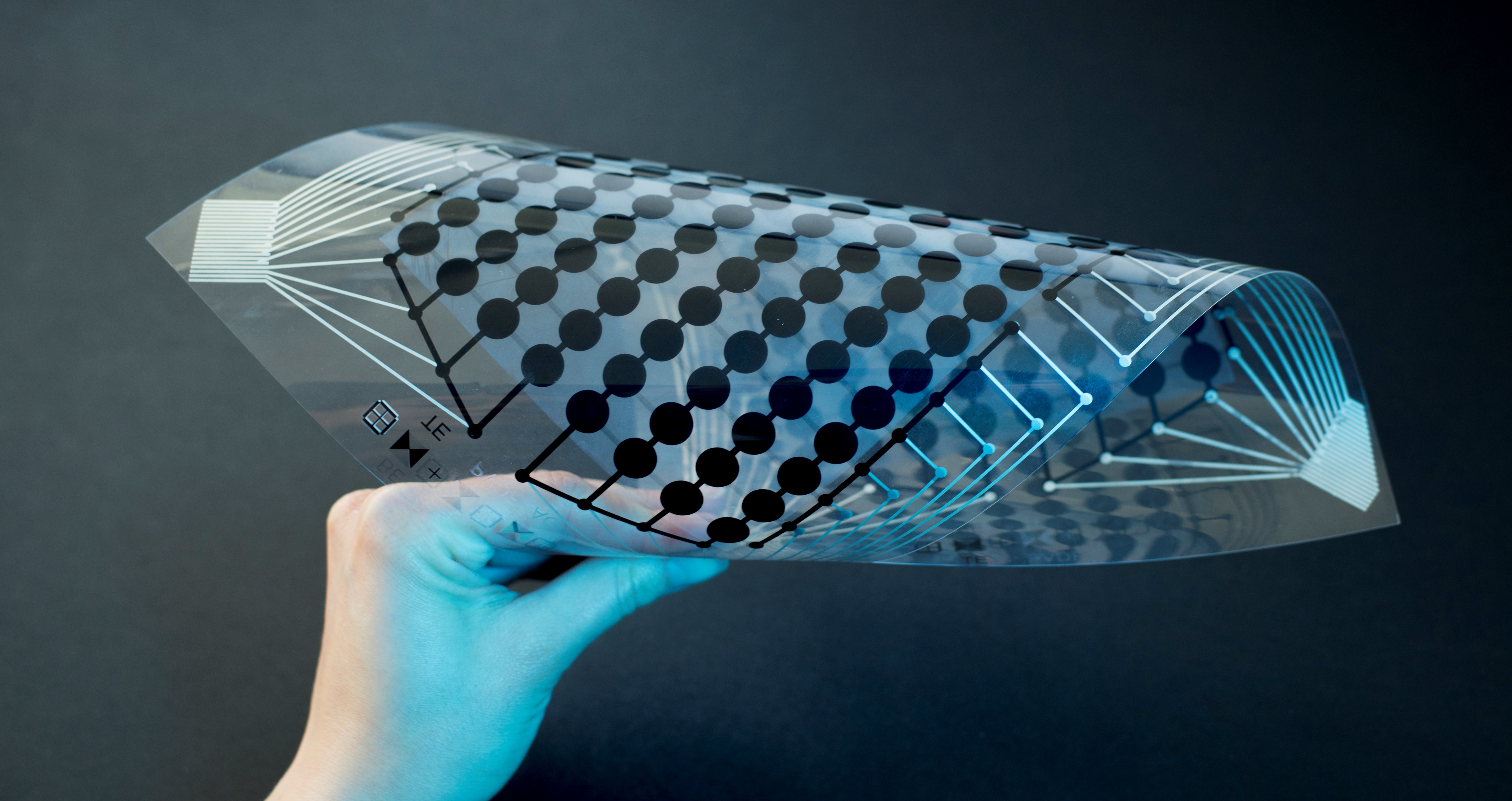

A new material development from Fraunhofer ISC takes the flexible display technology one big step forward. Printable sensor materials applied to a film can register deformations and transmit their signal directly and in high resolution to a computer. Combined with a flexible display, both tablet PCs and smartphones will not only be operable via virtual switches and buttons but also by means of bending and moving the film.

Signal by means of deformation

The sensors that were developed within the framework of the EU project “Flashed” are made from innovative piezoelectric printing pastes. They can be extensively applied to a flexible polymer film and allow for the installation of electronic printing sensors with a simple printing process. The sensitive surface of the film – when it is connected to a display, for example – measures the deformation when touched. The resulting signal can be digitalized and spatially depicted. The new touch sensor technology will fundamentally change the operation of mobile end devices since the new types of sensors enable a more intuitive control – without switches, buttons or swiping function.

Not only pressure but also temperature sensitive

The sensors, which are inexpensive to manufacture, register not only changes in the mechanical pressure – for example when the flexible display is bent and moved – but also changes in temperature. This also makes them applicable as proximity sensors. Even the smallest change in temperature – such as when a hand approaches the sensor – triggers a corresponding signal. However, this effect can also be suppressed by the developers, if it is not needed. In the case of the FLEX SENSE display, it is advantageous to completely switch off the temperature sensitivity in order to attain a higher local resolution. In addition, the sensors can also be used as actuators to enable haptic feedback. The combination of sensor characteristics with haptic feedback can improve the user-friendliness of many applications and increase the range of functions.

Lead-free in the future

Lead titanates have been used in sensors up to now. This material, which has been classified as harmful to health, is to be eliminated in the future. Therefore, an important goal is to replace piezo materials containing lead with other materials without losing too much of the sensitivity. New ferroelectric particle matrix systems are being developed within the framework of the project and are being adapted to current screen printing processes.

Fraunhofer Materials

Fraunhofer Materials