Within the framework of the EU-funded “LIMOWOOD” project, researchers at the Fraunhofer Institute for Wood Research WKI and partners from the industry have developed WPC panels for furniture that are flame retardant and moisture-resistant.

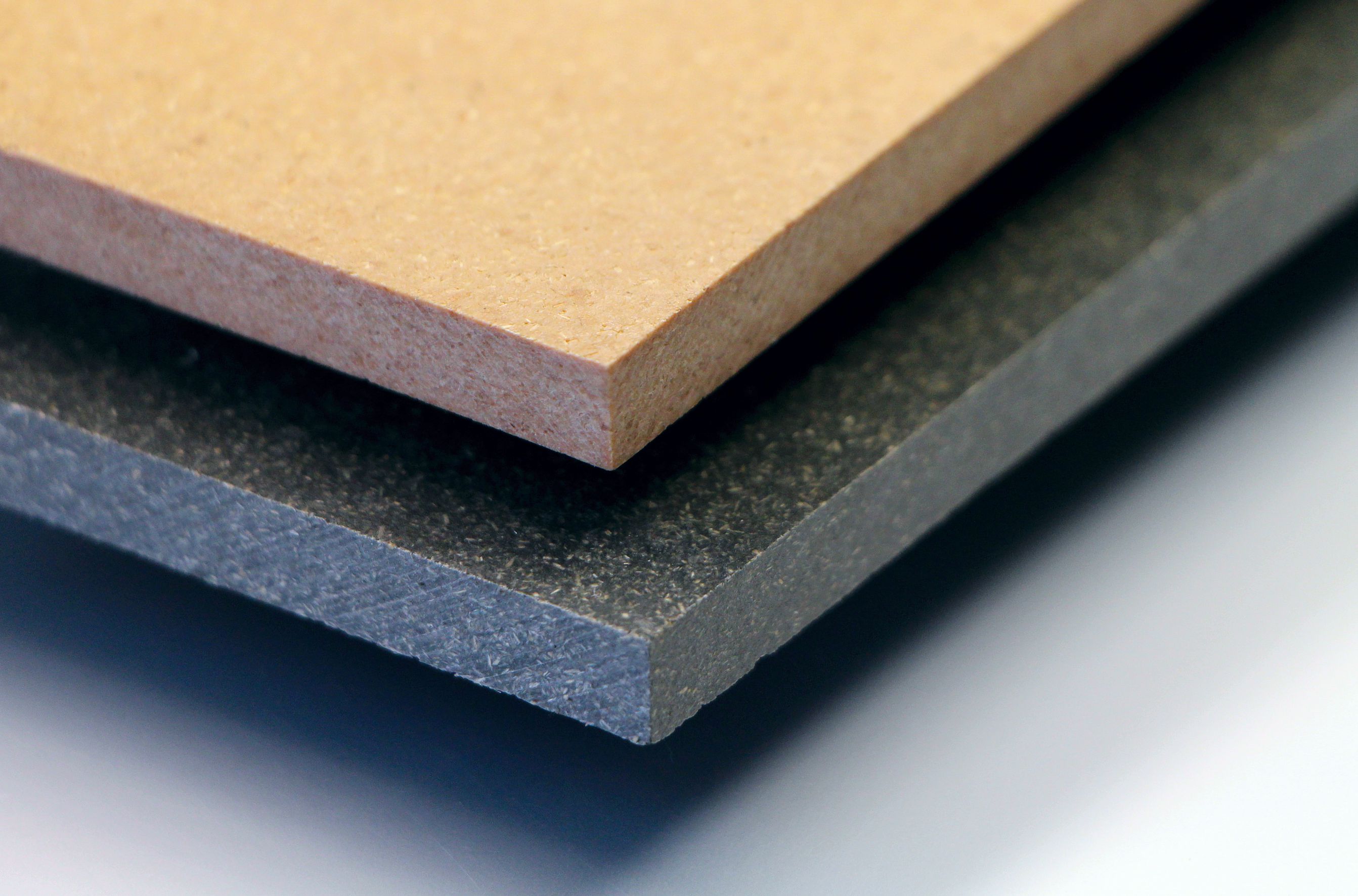

The material is composed of up to 60 percent wood particles and 40 percent thermoplastics, particularly polypropylene and polyethylene. The raw materials can stem from recycling streams. Other raw materials containing lignocellulose like rice hulls can be used to manufacture the panels. Researchers at WKI produce WPC panels by press molding without using formaldehydecontaining glue. The materials are 100 percent recyclable.

Commercial, halogen-free flame protection agents were added during compound production. Researchers obtained the best results with a combination of flame protection agents like red phosphorous and expandable graphite. These WPC formulations displayed oxygen indexes of up to 38 percent when flameprotected wood particles were added at the same time. For comparison: The oxygen index of a non-flame protected WPC panel is only at 19 percent. In a small burner test, the flameprotected panels did not ignite even after exposure to the flame for 300 seconds.

Additionally, the WPC panels absorb only little water and are therefore particularly suitable in humid environments. The application of WPC reaches its limits only where high static loads occur.

A skillful selection of components made it possible to achieve a high bending strength that exceeds the requirements for particleboards. This makes the application of flame-protected WPC possible not only in furniture but also for facade cladding, exhibition stand construction and in the building and transportation industries.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials