New polymers and additives for practical tests

There is almost no limit to the selection of different polymers available on the market. So the right types of materials are available for a large majority of application areas. In addition, the property profiles of a polymer can be precisely customized for each application by applying the right additives.

Despite or precisely because of these myriad possibilities, new questions keep occurring such as how polymers can be designed more inexpensively, more efficiently or with more resistance compared to commercially available polymers and additives.

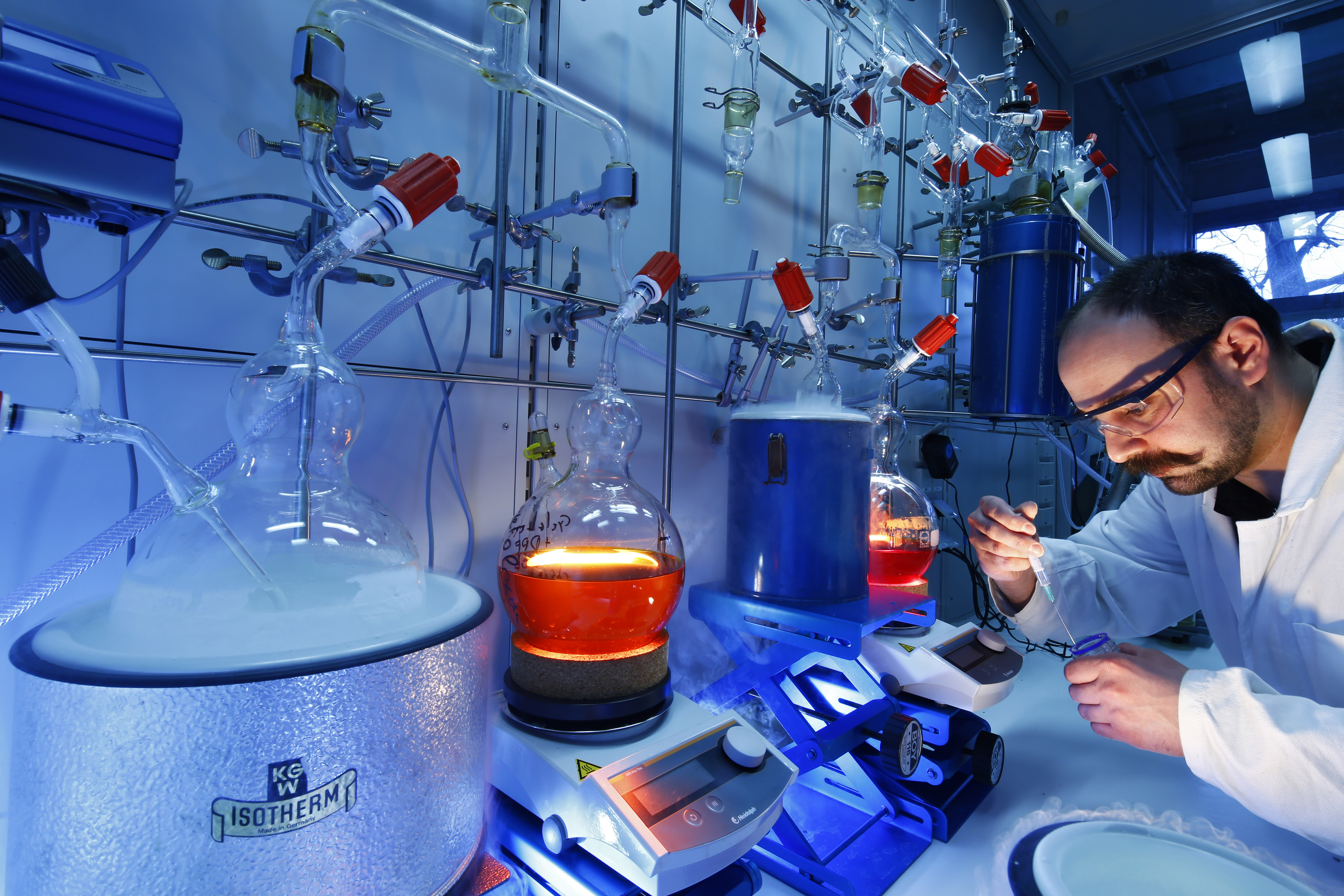

In the area of polymers, Fraunhofer LBF is creating and testing new polymers and additives by means of chemical synthesis in order to provide solutions. Normally, first chemical experiments are carried out with small amounts in a synthesis laboratory to spare resources, avoid waste and to detect potential danger at an early stage. The result is approximately a few grams of substance, which is enough for first application-oriented tests.

However, this amount is not enough for practical tests carried out with customers or at the institute. In order to bridge this gap, a kilo laboratory in the field of polymers was set up which enables the synthesis of several kilograms of polymers and additives that were previously developed in conventional laboratories.

The kilo laboratory is equipped with different reactors that allow for reactions under different conditions, like inert gas atmosphere, pressure or under very low or very high temperatures. A corresponding periphery for the reconditioning and cleansing of the reaction products is available as well. Classical organic syntheses as well as different polymerization methods, particularly controlled radical and live ionic polymerization, are possible.

This method enables the manufacture of, among other things, polymers with special architectures that are suitable as bonding agents and compatibilizers. The kilo laboratory is used to work on customized solutions for the manufacture of innovative components and materials.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials