Equipping new components or materials with additional functions has been a trend in product development for years. The Fraunhofer IFAM in Bremen is responding to the current demand for more functional integration with the material class of "functional polymer composites" developed there.

The material concept is based on thermoplastic polymers, in their classic characteristics or as soft-flexible elastomers. Innovative compounding techniques, combined with the desired fillers, generate high-performance plastic composites for a wide variety of applications. Both metallic microfibers and powders of various types can be used as fillers. In the appropriate case, these can be combined with low-melting alloys. Furthermore, all carbon-containing as well as ceramic additives can be compounded into the respective matrix polymers. Filler contents of over 80 % by weight can be easily achieved with this technology and lead to functions in the plastic that come very close to the properties of the corresponding fillers.

Electrical conductivities of high 106 S/m can be achieved as well as thermal conductivities of more than 10 W/mK. A further large area of application is the functionalisation of the material with regard to its use in the field of EMC protection. Here an analogue damping behaviour can be achieved over a very wide frequency range in comparison to purely metallic materials. In addition to the physical properties, the "functional polymer composites" show further special features. Despite of their high possible contents, the materials still exhibit a good spectrum of mechanical properties as well as processing behavior. The composites can thus be processed with the established production technologies of the plastics industry, with minor adjustments in the process.

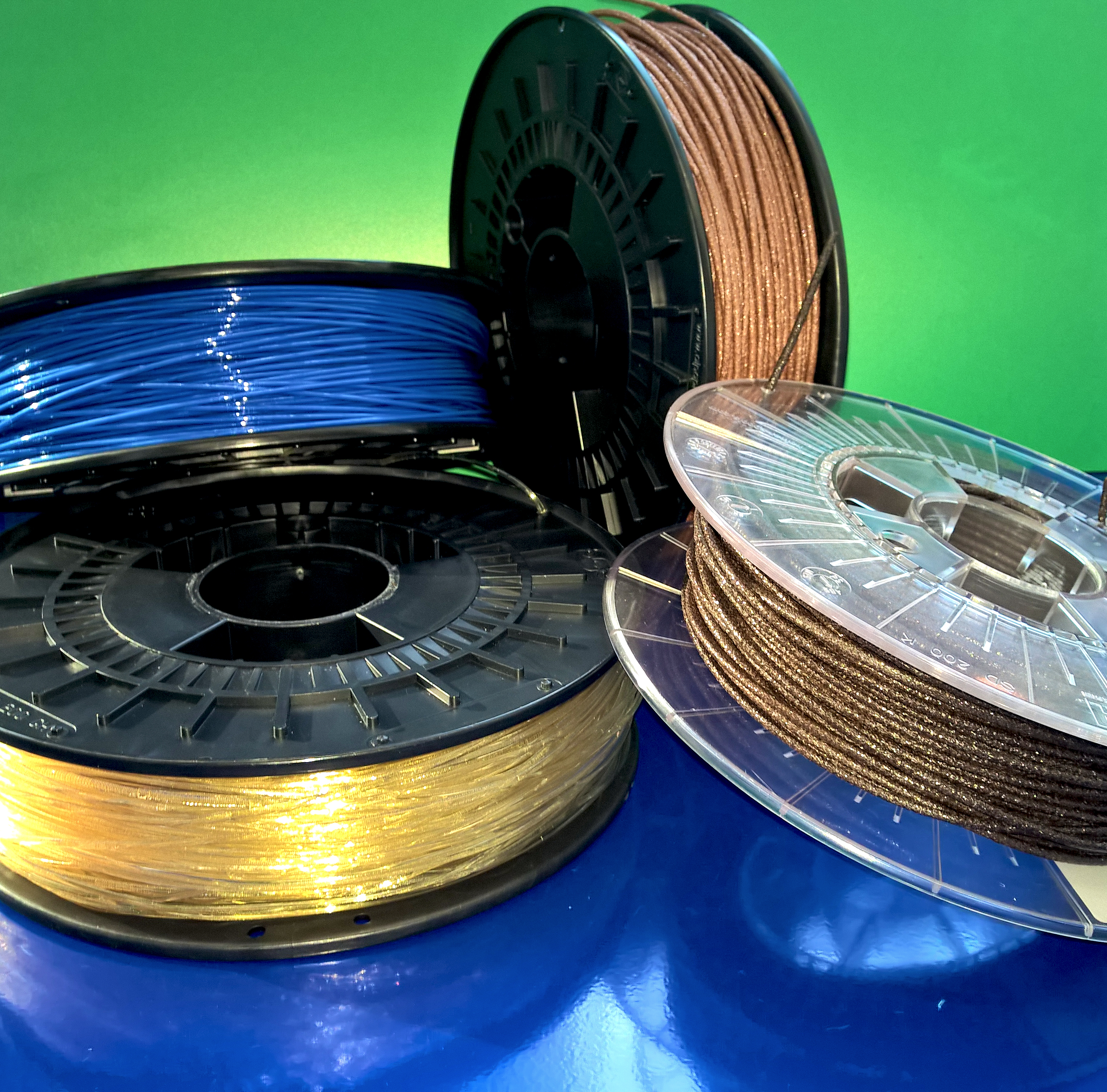

By means of extrusion or injection moulding (especially with multi-component injection moulding or extrusion), function-integrated components can be produced efficiently and at minimum cost. The processing portfolio of composite materials is currently being supplemented by FFF printing. In terms of technology, a special production line for highly filled polymer composites has been created on which the various material variants can be processed into a correspondingly printable filament.

Functional polymer composites make it much easier to integrate additive functions into a component. Thus, new applications can lead to new or improved product ideas, and good technical solutions can be developed if necessary.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials