Biogas is usually converted into electricity or biomethane and fed into the respective grids. Since the feed-in rates are determined mostly by the prevailing funding policy, the 8000 existing biogas plants in Germany have strong incentives to find new ways to operate profitably without having to rely on state funding.

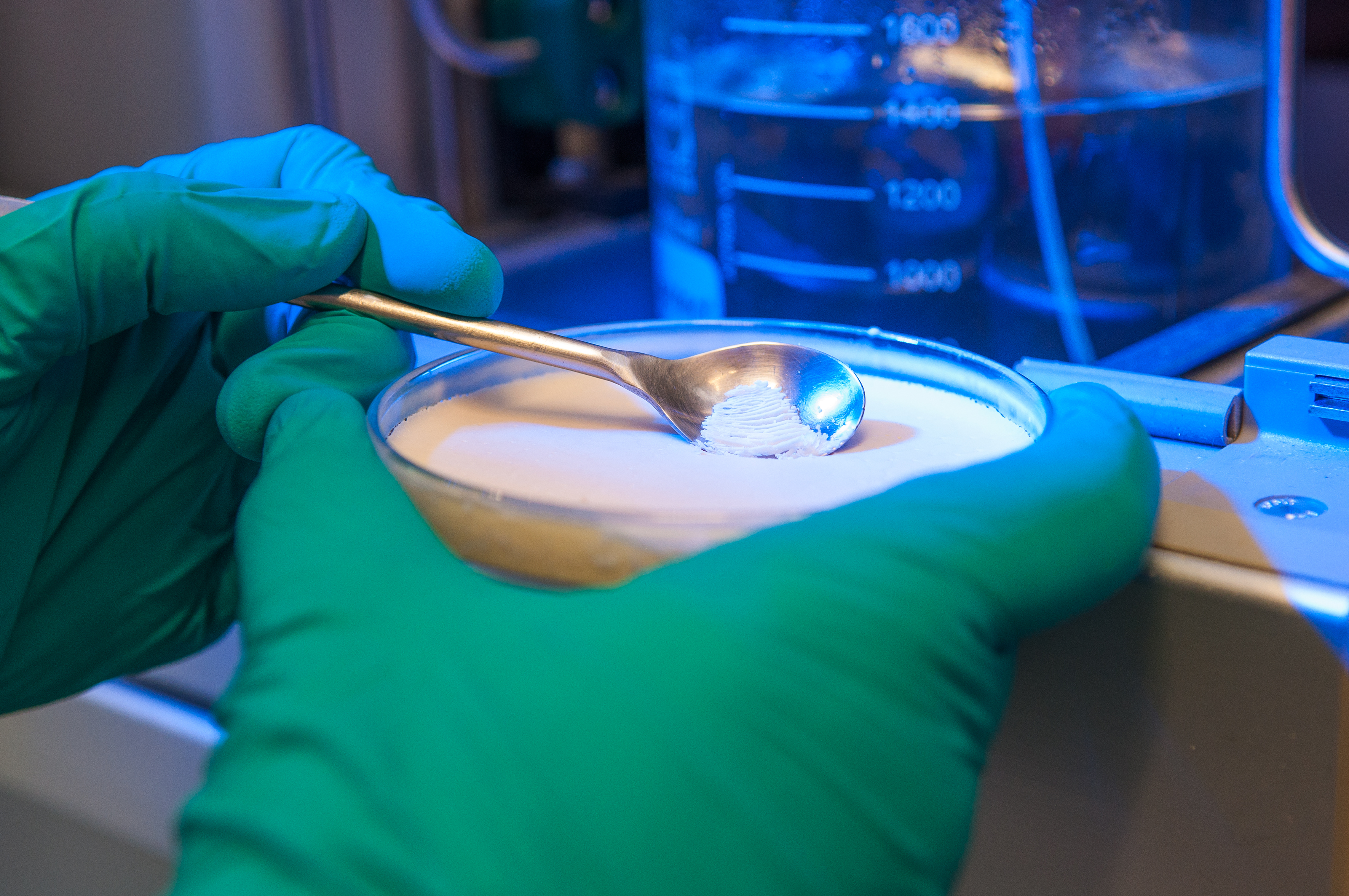

The use of biogas to produce high-quality chemical products is one potential alternative. Biogas consists of methane and carbon dioxide. Until now, carbon dioxide has mostly been classed as a waste product, although it can also be used to synthesize various kinds of waxes. The pertaining process involves producing syngas at very high temperatures and with the help of ceramic-based catalytic converters. Using a Fischer-Tropsch synthesis, the syngas is then used to synthesize high-quality, organic-grade wax.

Thanks to their high purity, theses waxes are of particular interest for the cosmetics industry. They enable lucrative potential applications, in particular for the natural cosmetics sector. Furthermore, biowaxes can also be used as lubricants. The purity of these waxes means that a defined product composition – and thus reliable product properties – can be guaranteed at all times, to a degree not offered by petroleum-based lubricants.

The three-year project, funded by the development bank SAB, was an in-depth investigation of this promising approach. The focus was, in particular, on the design and operation of a demonstration plant for wax production connected to a biogas plant. The process data received were used to evaluate and prove the economic viability of the approach.

Fraunhofer Group for Materials and Components - Materials

Fraunhofer Group for Materials and Components - Materials